Once the logs get there for the sawmill, they are sorted based on species, size, and high quality. This stage ensures that similar logs are processed with each other, optimising the efficiency from the mill and the standard of the finished product.

Durability: Rubberwood is known for its impressive longevity able to face up to the rigors of everyday use.

The following move in wood producing is joining. This process entails gluing collectively numerous items of wood to make a single, more substantial piece. This is accomplished utilizing adhesives, which create a solid bond amongst the two parts.

Despite the fact that we use NHLA (Countrywide Hardwood Lumber Affiliation) benchmarks as a manual, there are occasions when our standards are even greater. If we find a board that we believe would disappoint our client, we pull it out. If we will remedy the challenge by reducing out a foul location, We'll change 1 board into two.

The profitability of lumber production will depend on the mill’s ability To maximise the wood’s top quality throughout the full lumber manufacturing procedure.

By far the most critical phase in ensuring your woodworking is sustainable is to make use of materials which are sourced responsibly. Try to find components which might be Licensed as sustainable by organizations including the Forest Stewardship Council (FSC).

Wood producing is a traditional kind of manufacturing which has been applied for centuries. It's really a sort of producing that consists of reducing, shaping, and assembling wood into a number of products.

The kiln drying procedure may vary considerably, with regards to the species and First MC on the wood. On the whole, having said that, these are definitely the ways in the procedure:

The sustainability of the centrally positioned campus is excellent, with its weather-helpful timber hybrid style and its Vitality idea consisting of assorted regenerative Electricity sources such as warmth pumps and photovoltaic techniques that minimize the carbon footprint. Completely, this leads to the bottom achievable Power use with the greatest probable degree of independence – devoid of fossil fuels.

Kiln-drying: The lumber ซันไวส์ อินเตอร์เนชั่นแนล is then dried in kilns to scale back its dampness material. This stage is essential as it helps prevent the problems of warping and shrinkage and prepares the wood for an extended lifestyle as Element of a bit of household furniture.

With the likely for automation, renewable assets, and enhanced generation methods, wood producing is poised to become An important participant in the worldwide production industry.

From producing home furniture to constructing constructions, the end result is an item that is certainly both of those practical and aesthetically pleasing.

To the post-drying lumber processing, in-line moisture information measurement systems can easily identify and mark parts that happen to be both far too wet or also dry. These items can then be pulled within the production line in advance of even further processing And perhaps be re-dried or re-milled as important to create the highest grade lumber or wood component achievable for that piece, As a result raising the mill’s profits and offering people accessibility to better high-quality resources.

We observe this by chopping smaller samples through the boards. If stress develops, we use steam to add humidity back again in to the kiln. This moistens and relaxes the outer part of the board till the inside finishes drying.

Bug Hall Then & Now!

Bug Hall Then & Now! Amanda Bearse Then & Now!

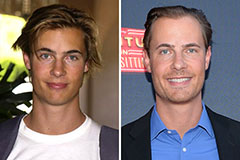

Amanda Bearse Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!